Project 22 Independent competent person appointment

February 2021 Update

Project Update, November 2020

Progress has been steady as much of the background work progresses. We recently decided, to focus mainly on the compliance side for the project. This covers the design , development and the production of the locomotive.

Our main areas of activity have focused on:

* Computer-Aided Design

* Purchasing drawings

* Research into documents and manuals

* Compiling a components’ list

* Locating critical components

* Safety and compliance of the build

* Appointment of the projects ICP (Independent competent person)

COMPUTER-AIDED DESIGN (CAD)

In September 2017 we gained a new Committee Member, Andrew Thomas who is a full-time CAD engineer working in an industrial business. Andrew has taken on the role at Project 22 as Head of Design Engineering.

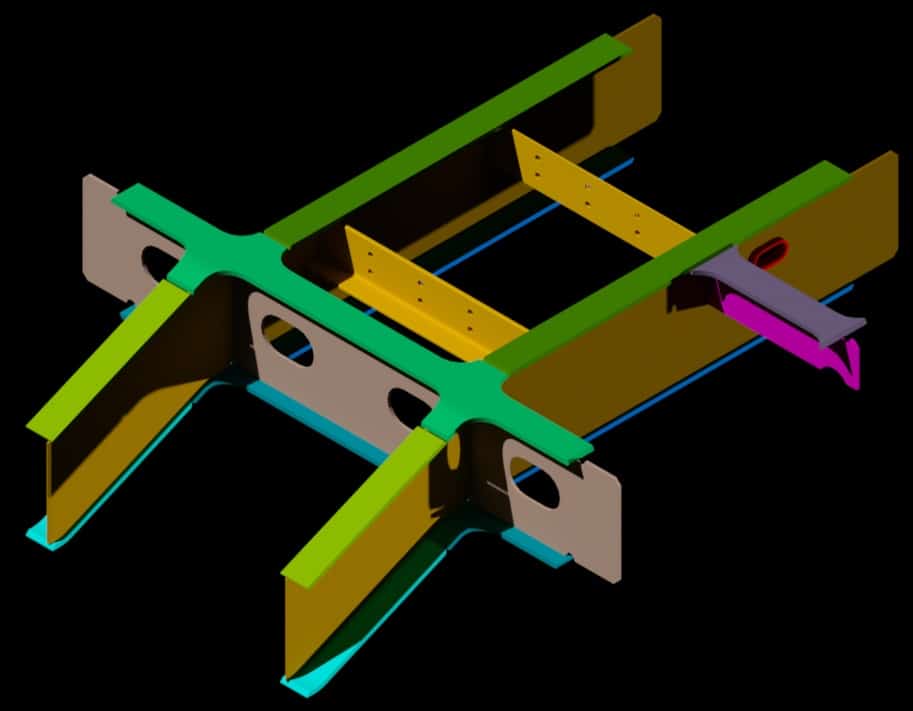

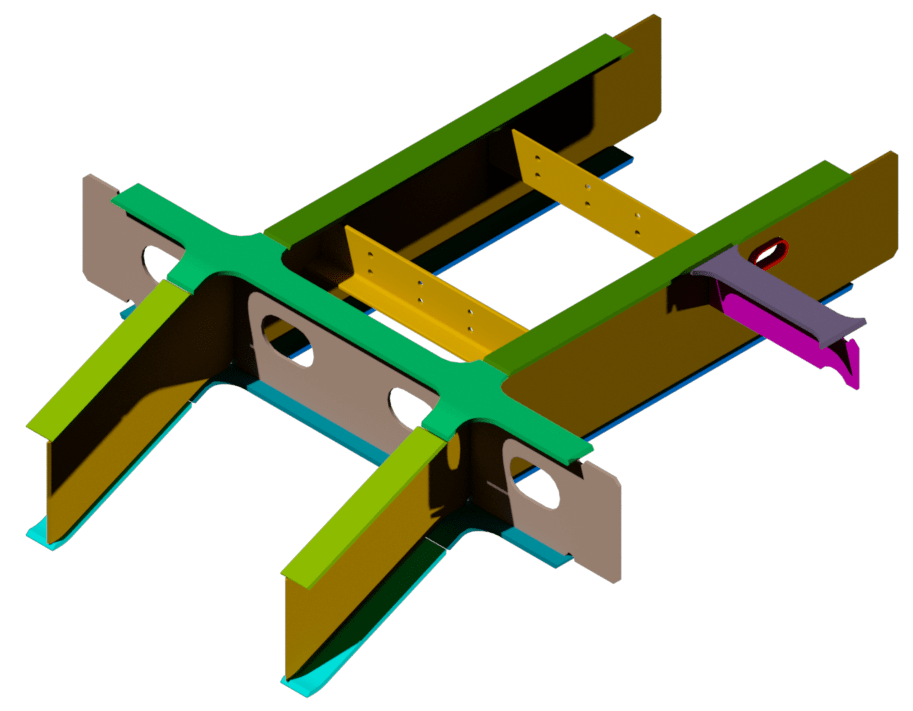

Andrew’s work is intense and time-consuming, and provides Project 22 with the critical drawings needed to gain the costings for specific aspects of the project. Andrew has been in close discussion with the now appointed ICP for Project 22, and ensuring we answer all the questions regarding safety, construction, production and compliance to name just a few. Above are the first two rendered CAD images of the Mainframe stretched assembly, the as you can see identify the individual parts through the colouring of said parts.

Independent competent person

In November 2020 Project 22 appointed an Independent Competent Person (IPC), this a very important role for any new build project and below is an explanation of why this is and what they do and cannot do for us.

Safety verification by an Independent Competent Person is required by the Railway and Other Guided Transport Systems (Safety) regulations 2006 (ROGS) for new and altered rolling stock projects and is the regulatory regime for rail safety including, mainline railway, metros (including London underground), tramways, light rail and heritage railways.

The IPC should be involved in: –

- The design selection process.

- Identifying or setting standards and conditions for the verification process.

- Setting out the inspection and assessment plan.

The Office or Rail and Road (ORR) expects the IPC to guide, advise and challenge but not instruct or approve, but the operator (Project 22) carries the responsibility for producing safe equipment and operating it in a safe manor.

Safety Verification provides a process to ensure safety standards and performances are maintained on the project, the IPC’s task is to help the operators devise and carry out effective safety verification, mainly by checking the operator’s arrangements, based on information provided by the operator.

The operator must consider the views or recommendations of the IPC, but may challenge them, and ultimately reject them if they wish.

The ORR expects the operator to work with the IPC to overcome any difference of view.

The Safety Verification Scheme is a written specifically for the project as it develops and will usually cover the following points: –

- Selection of IPC and appointment details, communication arrangements etc.

- Requirements and intended purpose of the project.

- Design criteria and standards adopted or set.

- Examination and testing.

- Making and preserving records of:

- Testing and examinations.

- Remedial actions recommended.

- Remedial action performance.

- Communications from IPC to relevant operator’s SMS duty.

The IPC will normally use systems engineering principles to verify safety arrangements are complete and robust throughout the project from design selection to testing and on-going maintenance.

It is necessary for the IPC to draw up written reports at various stages culminating in a letter to the operator explaining his findings and recommendations.

The process should assist the operator produce a robust and efficient safety case with a satisfactory outcome.

We at Project 22 are in the very fortunate position of having access to copies of virtually all of the original North British Locomotive Co. Ltd. drawing but it is not as simple case of build the locomotive to those drawings and we can operate it.

At all stages throughout the build we have to proceed in the correct manor, keep records of our design decisions, for example which modern steel specifications to use to replace those quoted on the original drawings, justification as to which fabricators we use, their competence and experience in the relevant field of manufacture, refurbishment or replacing of components used in the locomotive etc.

Having an experienced ICP involved is a great bonus to us, advising how to proceed correctly at all stages and he will help prevent us making mistakes due to lack of experience.

Recent Comments